Octane Rating

Why should you read the octane rating at the gas pump? The compression ratio of your engine determines the octane required for optimum performance. The octane rating of gasoline states the level fuel that can be compressed before it ignites. Under extreme conditions such as heavy acceleration fuel can ignite without the use of the spark plug resulting in a "ping" or "pinging" and under ultra heavy condition a knocking sound. When this condition is left un-treaded it could result in sever engine damage.

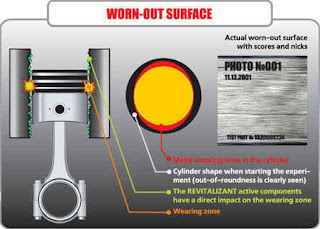

The compression ratio is the number that can be used to help predict the engine performance. It is calculated by taking the volume of the cylinder, when the piston is at the bottom of its stroke, and then dividing it by the volume when the piston is at the top of the stroke, the higher the compression ratio the more power your engine can produce, The extra power produced is coupled with added efficiency in turn help improve gas mileage.

Checking Compression

To check compression you must first disable the ignition system to keep the engine from starting. Locate the ignition coil and disconnect it, or unplug the ignition module connector. To test if the ignition is disabled crank the engine over, the engine should not start. With the engine warm remove one of the spark plugs and insert the compression tester into the spark plug hole. Now turn the key of the engine for at least 5 to10 seconds to get an accurate reading. Repeat this for each cylinder of the engine and record your results relating the reading to the individual cylinder. If the individual readings vary by more than 10% between cylinders you may have a problem.

Optional compression testing methods include an electric starter tester. This test measures the battery amperage draw to each cylinder while the engine is cranking. It will show you which cylinders have good compression and which have the least compression. In a gasoline engine a moderate compression ratio is needed, around 140 to 160 pounds per square inch. Each manufacturer produces specific compression ratios for their engines to closely control the power output and emissions. If high compression exists it can cause a problem known as pre ignition or detonation. A compression test can detect internal combustion malfunctions such as, bad valves, bad piston rings, or excessive carbon build up. These problems if left un-repaired can cause more extensive engine damage and even catastrophic failure.

No comments:

Post a Comment